The basic principle of a horizontal fermentation tank for organic fertilizer is high-temperature aerobic fermentation, which can be used to treat various organic waste such as animal manure, organic waste residue, and crop straw.

The basic principle of a horizontal fermentation tank for organic fertilizer is high-temperature aerobic fermentation, which can be used to treat various organic waste such as animal manure, organic waste residue, and crop straw.

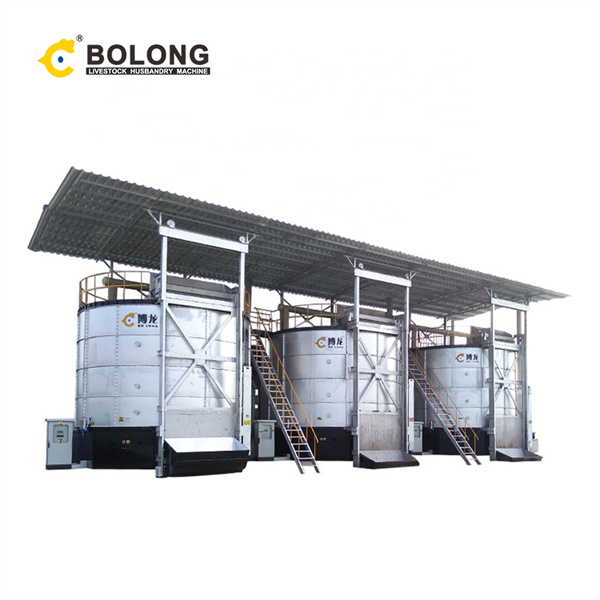

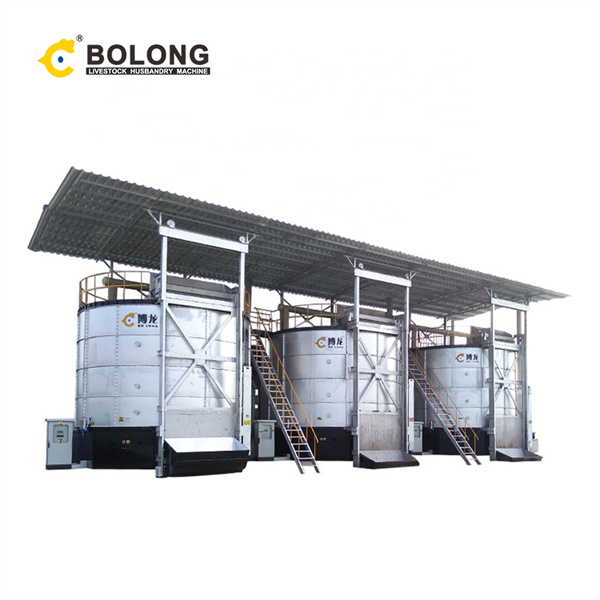

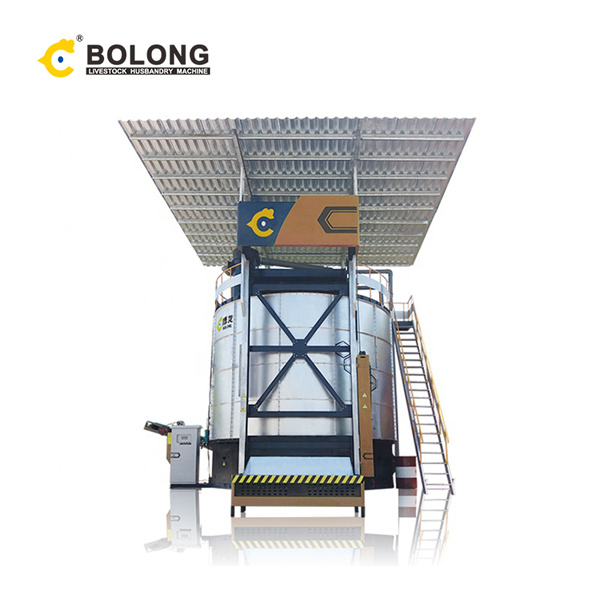

Description. Introduction to aerobic fermentation equipment: The aerobic fermentation tank equipment is mainly composed of fermentation chamber, feeding lifting system, high-pressure air supply system, main shaft drive system, hydraulic power system, automatic discharge system, deodorization system and automatic control system.

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

Poultry Chicken Manure Food Waste Composting Organic Fertilizer Fermentation Tank, Find Details and Price about Agricultural Machinery Poultry Farm Equipment from Poultry Chicken Manure Food Waste Composting Organic Fertilizer Fermentation Tank - Yantai Fuye International Trade Co., Ltd.

Farm Machinery Poultry Manure Composting Organic Fertilizer Fermenter Fermentation Tank, Find Details and Price about Fertilizer Equipment Agricultural Machinery from Farm Machinery Poultry Manure Composting Organic Fertilizer Fermenter Fermentation Tank - Yantai Fuye International Trade Co., Ltd.

STRUCTURAL COMPONENTS The whole equipment mechanismis divided into three parts, the lowerbase part is distributed with hydraulicstation, vortex air pump, oil cylinder.heating system and stirring shaft; ltis lined with 304 stainless steel plate,the middle interlayer is filled withpolyurethane foaming agent, and theouter wall is made of thickened steelplate to

Chicken manure co-fermentation regularly has better results than chicken manure fermentation as a monosubstrate. The low methane yield was observed only for studies that used switchgrass (2 mL/g VS) , straw (4.34 mL/g VS) , and glycerol after biodiesel production (6.34 mL/g VS) . In general, methane output in co-fermentation was in the

Purpose: Poultry manure (PM) is a concern for Bangladesh. The improvement of quality and safety is always desirable. The experiment assesses the quality and safety

2021/1/19/ · Dwindling fossil fuels, and the rise in energy demand have urged us to explore alternative renewable energy forms. An integrated process of dark fermentation and microalgal cultivation to deliver biofuels are gaining momentum in recent times. In this study, in the first stage, the starchy wastewater (SWW) with poultry manure (PM) was treated

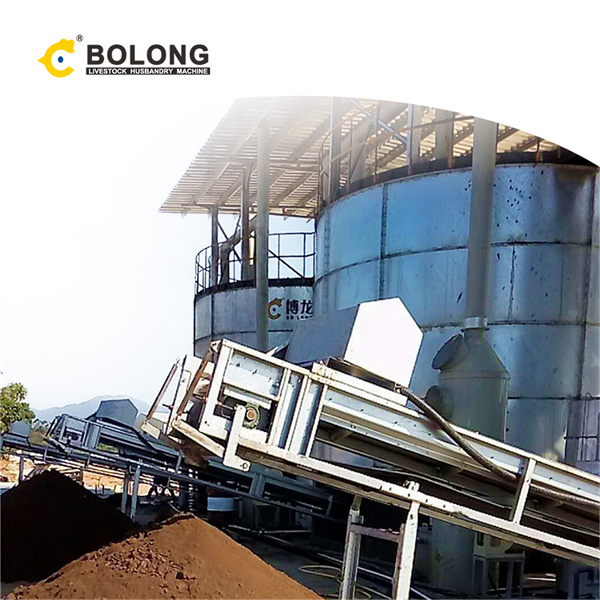

Animal Manure Composting Fertilizer Chicken Manure Fermentation Tank. Model Number:11FFG-102. Power: 11FFG-102 Installed 43KW, running 26KW. Samples: 11FFG-90 25-30 KW. Customization: Customized logo(Min. order 5 sets) GET QUOTE. Urban Sludge Fermentation Tank. Model Number:11FFG-160.

2015/1/1/ · Significantly, the fish from the FCM fertilized ponds had a better microbial quality which explains the advantage of using fermented chicken manure over raw chicken manure as at thermophilic anaerobic fermentation most bacterial pathogens are killed by exposure to temperatures of 55–66 °C for a few hours or less (Epstein, 1997, De León

2023/12/15/ · Vertical Fermentation Tank: Based on the nature of the solid phase in the rapid fermentation tank of organic fertilizer, chicken manure fermentation can be divided into two . One method is to use crops (such as bran, soybean cake, etc.) as a substrate for fermenting chicken manure. These substrates not only make up the solid …

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

We provide. Packaging And Transport. Quality Test Before Delivery. Check Items When Packing. After-sale Service. The livestock and poultry manure fermentation tank can process animal manure and animal carcasses such as chickens, pigs, cattle, sheep, and horses. Its processing capacity is 2~5 cubic meters per day. Free inquiry now!